Stihl – MS 261 C-M – Petrol Chainsaw

MS261CM (Stihl 2-MIX) 3.9hp petrol chainsaw with 14/16/18″ bar.

Very light, handy and powerful professional chainsaw. The electronic self-tuning engine management system means that the fuel supply is electronically controlled and the machine automatically adapts to operating and ambient conditions, ensuring optimal engine performance every time. The memory function remembers previous operating conditions and allows you to restart quickly after an extended break. With easy-clean HD2 filter, controlled-delivery oil pump and practical features such as a stainless steel muffler, captive nuts on the sprocket cover and monocoque cover with three quick release fasteners. The 2-MIX technology in the innovative STIHL MS 261 C-M ensures up to 20% less fuel consumption and up to 50% emissions reduction compared to the same power STIHL two-stroke engines without 2-MIX technology.

Any questions? Need assistance? Call our helpline on 01603 756128

Product Details

Standard Features

STIHL M-Tronic (M)

This fully electronic engine management system adjusts ignition timing and fuel metering in all operating modes. It also takes external conditions such as temperature, altitude and fuel quality into account. It ensures consistent engine performance, a constant maximum speed and superb acceleration. M-Tronic makes manual carburettor adjustments unnecessary. Thanks to electronic cold/warm start recognition, now there is only one start position on the combi-lever. The engine starts after fewer pulls and with no change of position, and can immediately accelerate up to speed - even after a cold start. M-Tronic also remembers the settings from the last time the tool was used. So when external conditions are the same, optimal engine performance is available every time you start up again.

STIHL 2-MIX-Engine

1-in-4 channel technology. The economical STIHL 2-MIX engine with 1-in-4channel technology features a high torque over a wide speed range. The chainsaw provides fuel savings of up to 20% compared to STIHL two-stroke engines in the same performance class without 2-MIX technology. Exhaust emissions are reduced by up to 50%.

HD2 Filter

The HD2 filter is made from polyethylene filter material with up to 70% finer pores than fleece and polyamide filters to trap even very fine dust. In addition, it is oil and water-repellent and thus very easy to clean. The PET-covered filter cartridge with quick-release lock enables the filter to be assembled and disassembled in next to no time, without using tools.

Decompression Valve

The decompression valve is part of the easy starting system. The valve should be pressed before starting to reduce the compression pressure when starting, as well as reducing the effort needed to pull the starter rope. The decompression valve is semi-automatic; it must be pressed manually before starting, but then closes automatically.

STIHL ElastoStart

STIHL ElastoStart reduces the shock caused by the compression of the engine during starting. The compression shock is taken away from the user's joints and muscles through a spring or rubber element in the starter handle.

Side Chain Tensioner

The tensioning screw can be found on the side of the chain saw through the sprocket cover. This removes the need for contact with the sharp saw chain.

Variable-Displacement Oil Pump

Allows a precise, demand-based delivery of oil. It's possible to reduce oil production by up to 50% in the E position. For very long cutting attachments or very dry wood, an additional volume of oil can be added by the user. similar to illustration.

Tool Free Filler Caps

Special catches on the fuel and oil tanks for easy opening and locking without the need for tools.

Pre-Separation Air Filtration System

STIHL long-life air filtration systems with pre-separation achieve perceptibly longer filter life compared with conventional filter systems. Air drawn in is swirled. The larger, heavier particles are ejected. The pre-cleaned air is routed to the air filter via the pre-separator duct.

Stop Button Function

After the machine is turned off, the control lever immediately moves back into the operating position. This allows a warm machine to be restarted again immediately.

Compensator

This controller in the carburettor prevents the fuel-air mixture getting richer as the air filter becomes clogged. The correct quantity of fuel is delivered to the carburettor depending on the quantity of air passing through the air filter. This keeps the fuel/air ratio in the combustion mixture constant and hence also the engine power. The filter doesn't need to be cleaned until an appreciable drop in power occurs.

Captive Nuts

When changing the cutting attachment, you will not risk losing the nuts on the sprocket. The MS 261 is the first STIHL chainsaw to be equipped with the captive nuts. A great advantage for all users.

Advanced Combustion Technology

Four overflow channels swirl the fuel-air mix before ignition, allowing for optimum combustion and highly efficient performance. The result is lower fuel consumption and high torque across a broad rpm range.

Carburettor Heating (V)

By changing the chain saw from summer to winter operation, the intake air is pre-heated over the engine fins. This ensures that the carburettor does not ice up and you can continue working in freezing temperatures.

Ematic Chain Lubrication System

The Ematic chain lubrication system ensures pinpoint lubrication of the saw chain links and guide bar rails. When used with STIHL OILOMATIC saw chain, it will provide maximum lubrication, longer wear and less oil consumption than conventional methods of chain lubrication. The Ematic system can reduce bar oil consumption by up to 50%.

| Displacement cm³ | 50.2 |

| Power output kW/bhp | 3/4.1 |

| Weight kg 1) | 4.9 |

| Power-to-weight ratio kg/kW | 1.6 |

| Sound pressure level dB(A) 2) | 104 |

| Sound power level dB(A) 2) | 116 |

| STIHL Oilomatic saw chain pitch/type | .325" RS |

| Vibration values left/right m/s² 3) | 3.5/3.5 |

| Tank volume l | 0.50 |

| Oil tank volume cm3 | 270 |

The engine requires a mix of petrol and engine oil. Simply mix a Stihl 50:1 two-stroke engine oil with unleaded (95 octane) petrol. The simplest method is using a standard 5 litre fuel canister and to add 0.1 litres (100 ml) of Stihl HP 2 stroke oil, close and thoroughly shake the canister and the mix is ready to use.

For this machine we recommend either Stihl HP or Stihl HP Ultra engine oil.

Free delivery over £75

Free delivery over £75  01603 756128

01603 756128

View Larger

View Larger

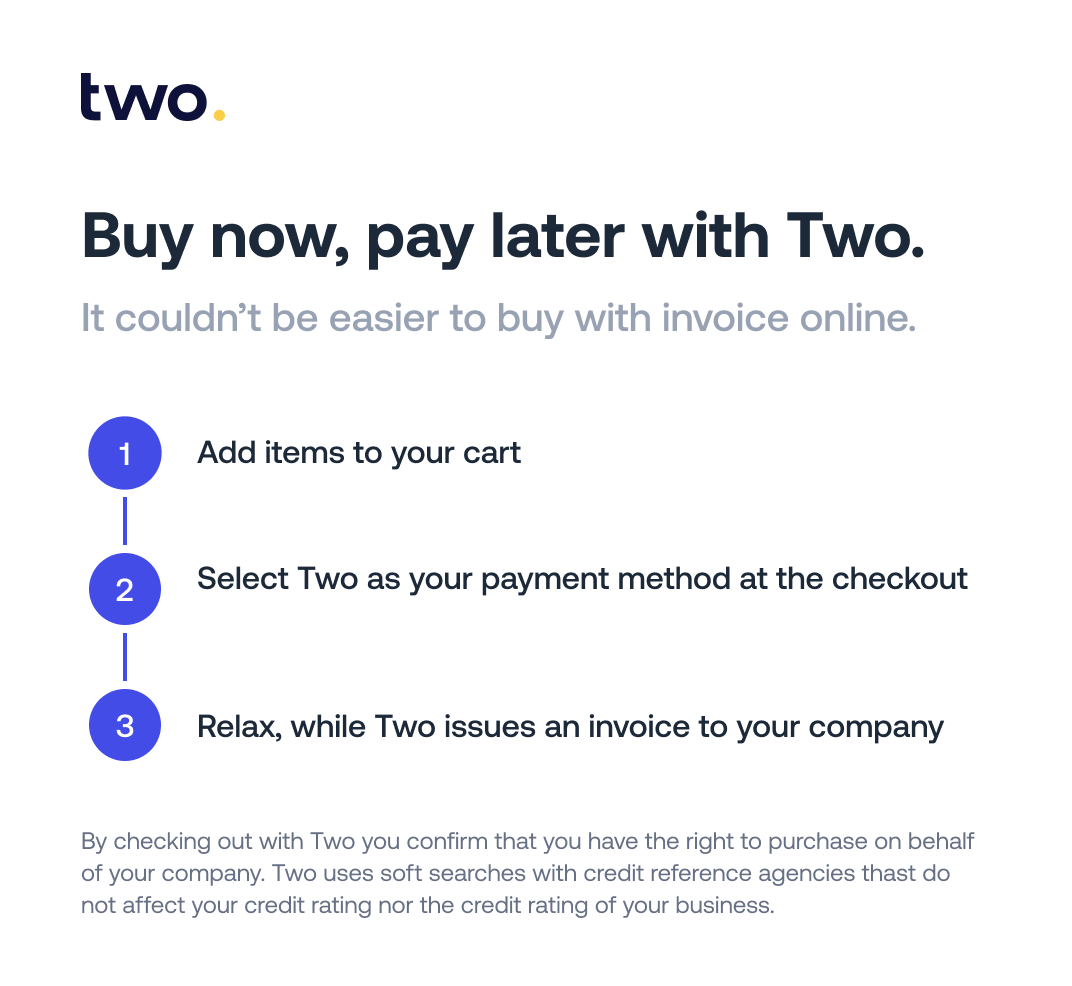

Go to checkout

Go to checkout